Webinar

Industry Standards and Best Practices for Continuous Thermal Monitoring

John Hope

Chief Technology Officer

Tulsi Patel

Technical Operations and Support Manager

Americas Timing

12pm Central Daylight Time

Americas Timing

12pm Central Daylight Time

04 December 2024

Maximize Resilience in Mission Critical Assets: How Predictive Maintenance is Becoming a Standard Approach

Explore how Continuous Thermal Monitoring (CTM) enhances critical electrical equipment reliability.

24x7 Hotspot Detection

Early identification of temperature rise in bus duct and bus bar power distribution systems

Bus duct joints are typically the weak spots

Heat, stress and vibration compromise the joints

Joints can become loose and corrode over time

Reducing conductivity and can result in power failures

2025 CTM Survey is now live!

Driving the evolution from periodic maintenance to

predictive maintenance. Your insights matter.

It takes less than 2 minutes.

Let’s power the change together.

Bus Duct Monitoring Solution Brochure

Build resilience into power distribution systems

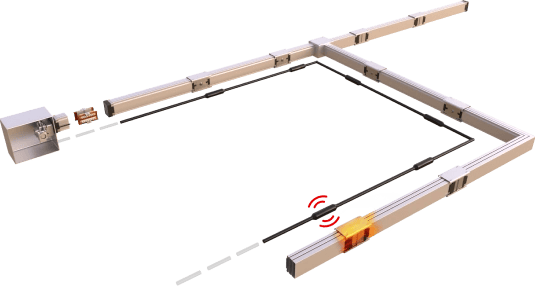

The Bus Duct Monitoring Solution matches the modularity of bus duct for electrical power distribution. It's quick and easy to install, and just as versatile.

The solution gives users a call-to-action on a specific bus bar or bus duct joint which is potentially faulty and needs attention before a more serious problem occurs.

Continuous monitoring of these electrical joints provides a 24x7 early warning system to detect critical temperature rise and reduce the risk of power loss.

Benefits

Save money

Reduce CAPEX and OPEX by eliminating the need for thermographic inspection. Operators will also save by avoiding the cost of unplanned electrical outages.

Enhance safety

Improve personnel safety across your facility by minimizing the need for staff interaction with faulty, compromised, or potentially dangerous electrical assets.

Increase efficiency

Build in greater resilience by protecting your operation against the inconvenience of unplanned downtime, and the risk of failing to deliver on end customer requirements.

Features

Identify potentially faulty bus duct joints before a more serious problem occurs

Simple installation

- Works straight out of the box

- Attaches quickly and easily

- Sensors fit directly to joints

- No complex commissioning

Flexible solution

- Modular build

- Install at the same time as bus duct

- Fits all complex bus duct systems

- Maintenance free

Data integration

- Digitally transform electrical assets

- Provides 24x7 temperature and alarm data

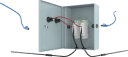

- Modbus 485 data taken direct to EPMS/BMS

- Monitor trends over time

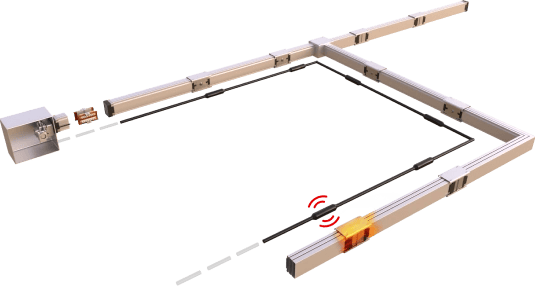

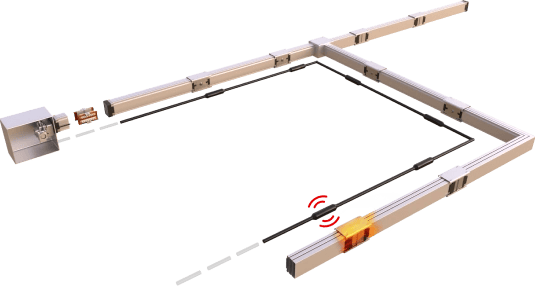

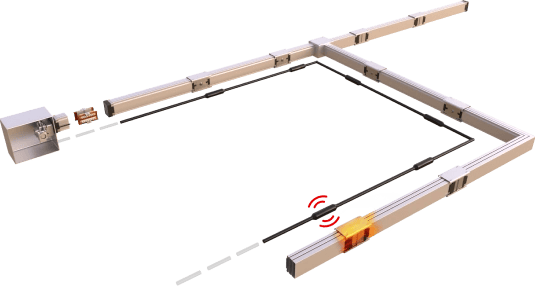

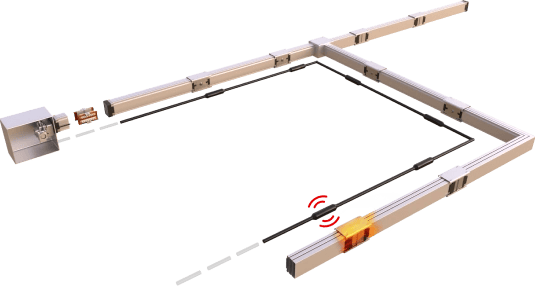

See how bus duct monitoring works

Identify potentially faulty joints

- 1Modbus datacard connectivity

- 2Sensors alert operators

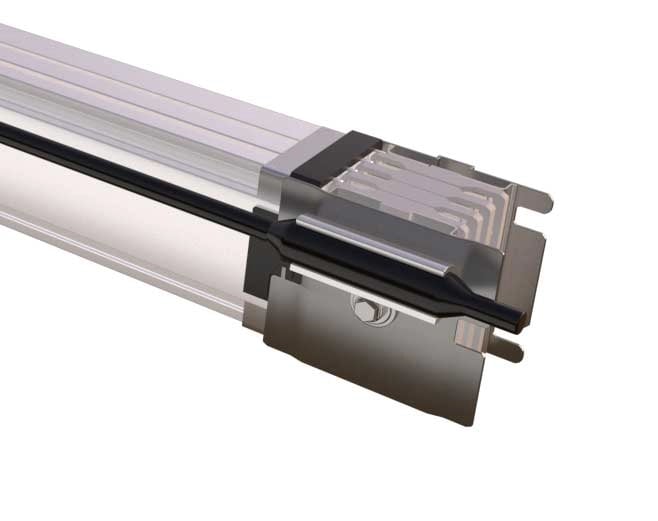

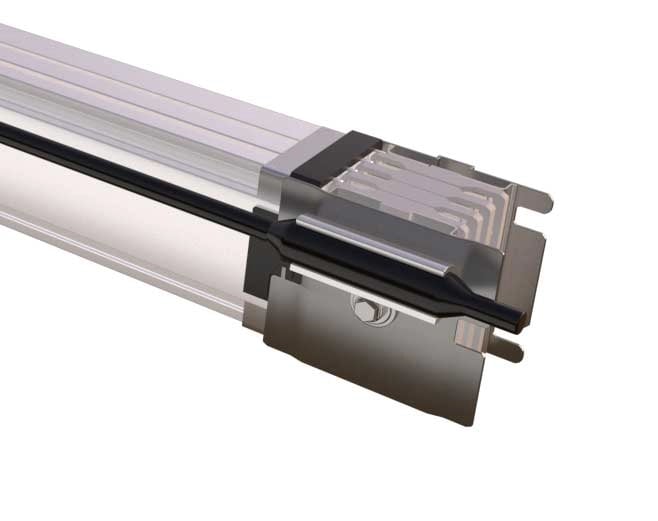

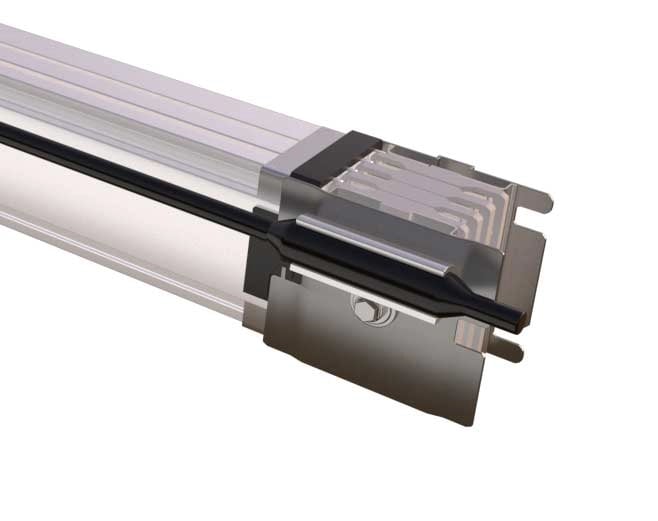

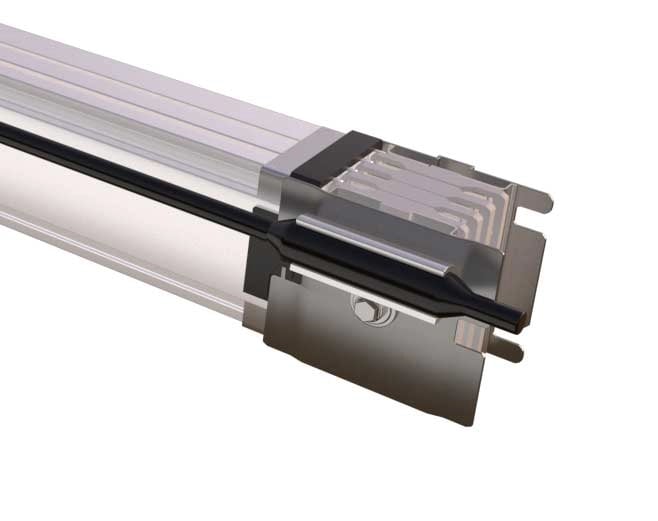

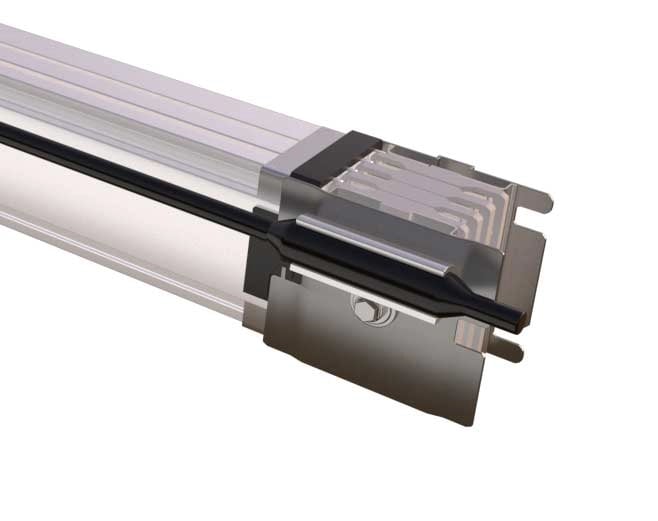

- 3Simple C-clip attachment

- 4Sensors align with joints

- 58 sensors over 24m lengths

Sensor cables ‘daisy chain’ together with simple modbus datacard connectivity

Sensors alert operators to a specific location when a change in temperature occurs

Simple C-clip attaches cables to bus duct joints

Sensors correspond to bus duct sections and align with joints

Sensor cable supplied in 24m lengths comprising 8 thermal sensors

Sensor cables ‘daisy chain’ together with simple modbus datacard connectivity

Sensors alert operators to a specific location when a change in temperature occurs

Simple C-clip attaches cables to bus duct joints

Sensors correspond to bus duct sections and align with joints

Sensor cable supplied in 24m lengths comprising 8 thermal sensors

Sensor cables ‘daisy chain’ together with simple modbus datacard connectivity

Sensors alert operators to a specific location when a change in temperature occurs

Simple C-clip attaches cables to bus duct joints

Sensors correspond to bus duct sections and align with joints

Sensor cable supplied in 24m lengths comprising 8 thermal sensors

Sensor cables ‘daisy chain’ together with simple modbus datacard connectivity

Sensors alert operators to a specific location when a change in temperature occurs

Simple C-clip attaches cables to bus duct joints

Sensors correspond to bus duct sections and align with joints

Sensor cable supplied in 24m lengths comprising 8 thermal sensors

Sensor cables ‘daisy chain’ together with simple modbus datacard connectivity

Sensors alert operators to a specific location when a change in temperature occurs

Simple C-clip attaches cables to bus duct joints

Sensors correspond to bus duct sections and align with joints

Sensor cable supplied in 24m lengths comprising 8 thermal sensors

Why Choose Exertherm?

Exertherm has a history of technological innovation spanning over 30 years. As a world leader in thermal monitoring of electrical and mechanical infrastructure, we have developed a suite of solutions to help build resilience into power distribution networks.

24x7 Thermal Monitoring

Simple Installation

Increase Team Safety

Zero Maintenance

NFPA 70B Compliant

Need more info? Let's talk

Get in touch to find out more about Bus Duct Monitoring by filling in the form. One of the Exertherm team will reach out to learn more about your requirements as soon as we can.

Need technical help?

Reach out to an expert for support

Commercial enquiries

Our sales team can help you