Webinar

How CTM Technology Powers Industries: Understanding the Technical Landscape

Learn how continuous thermal monitoring helps improve power distribution for global businesses

04 December 2024

Maximize Resilience in Mission Critical Assets: How Predictive Maintenance is Becoming a Standard Approach

Explore how Continuous Thermal Monitoring (CTM) enhances critical electrical equipment reliability.

Monitor critical bus bar and joint connections in medium voltage switchgear

Electrical failures are caused by a number of different factors, including:

The effects of constant thermal cycling on the joints

Corrosion of the metal components damaging insulation

Assets aging, mechanical damage, or environmental factors

Intrusion and human error as a result of maintenance processes

2025 CTM Survey is now live!

Driving the evolution from periodic maintenance to

predictive maintenance. Your insights matter.

It takes less than 2 minutes.

Let’s power the change together.

MV Switchgear Brochure

Protect electrical infrastructure with continuous thermal monitoring sensors

Continuous thermal monitoring technology enables critical MV switchgear joints and busbar connections to be monitored in real-time.

Thermal monitoring locations include:

- IR Sensors monitor Main Incomer Breakers, line and load side

- IR Sensors monitor ACB Feeders, line and load side

Benefits

The Exertherm® Medium-Voltage Switchgear Solution provides an early warning of potentially compromised LV assets before they fail, causing unplanned facility outages. The MV switchgear solution provides protection from thermal asset changes where the eye can’t see and the hands can't reach. Our unique ‘fit and forget’ 24x7 electrical infrastructure monitoring technology gives you the peace of mind that your assets are running safely.

Reduce the likelihood of electrical failures and improve operational stability with 24x7 monitoring.

Reduce human interaction with potentially faulty assets to increase personnel and on-site safety.

Reduce electrical fire or explosion risk resulting from arc flash due to compromised electrical assets.

Reduced the need for additional costs and the unnecessary intrusion of unplanned maintenance.

Features

The MV Switchgear solution from Exertherm is suitable for both new build and retro-fit installation, and also OEM vendor neutral.

Permanent installation

Permanently installed sensors for MV Switchgear mean you can fit and forget, only needing to return when a potential issue is flagged up.

Super efficient

This non-contact and non-powered solution creates it's own power supply from within the asset to monitor critical bus and joint connections.

Lifetime guarantee

We're so confident with the resilience built into Exertherm technology that we provide a lifetime guarantee on our sensor hardware.

Real-time data

Once installed our sensors work 24x7, 365 days a year to continuously monitor your critical electrical assets and provide condition data.

MV Switchgear Kit

- IR Sensor

- Exertherm Modbus Datacard

- ARM XL

IR Sensor

For busbar temperature monitoring

Exertherm Modbus Datacard

Collects data from 8 x IR Sensors

ARM XL

Panel mounted HMI for local status.

IR Sensor

For busbar temperature monitoring

Exertherm Modbus Datacard

Collects data from 8 x IR Sensors

ARM XL

Panel mounted HMI for local status.

IR Sensor

For busbar temperature monitoring

Exertherm Modbus Datacard

Collects data from 8 x IR Sensors

ARM XL

Panel mounted HMI for local status.

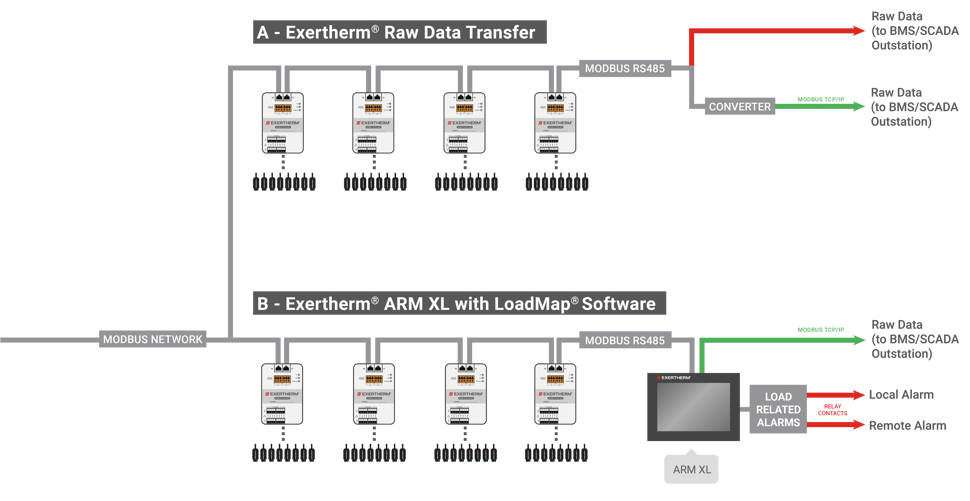

Connectivity

There are two connectivity options available:

Why Choose Exertherm?

Exertherm® is the global number one provider of 24x7 Thermal Condition Monitoring for electrical infrastructure, successfully installed worldwide by all major OEMs. We deliver complete solutions for LV/MV Switchgear, MCC Drawers, Dry Transformers and more. We’re so proud of our proven reliability we even offer a zero maintenance lifetime guarantee.

24x7 Thermal Monitoring

Simple Installation

Increase Team Safety

NFPA 70B Compliant

Zero Maintenance

Need more info? Let's talk

Get in touch to find out more about MV Switchgear by filling in the form. One of the Exertherm team will reach out to learn more about your requirements as soon as we can.

Need technical help?

Reach out to an expert for support

Commercial enquiries

Our sales team can help you

.webp?width=2000&name=2024%20CTM%20Survey%20Results%20Website%20webp%20(1).webp)